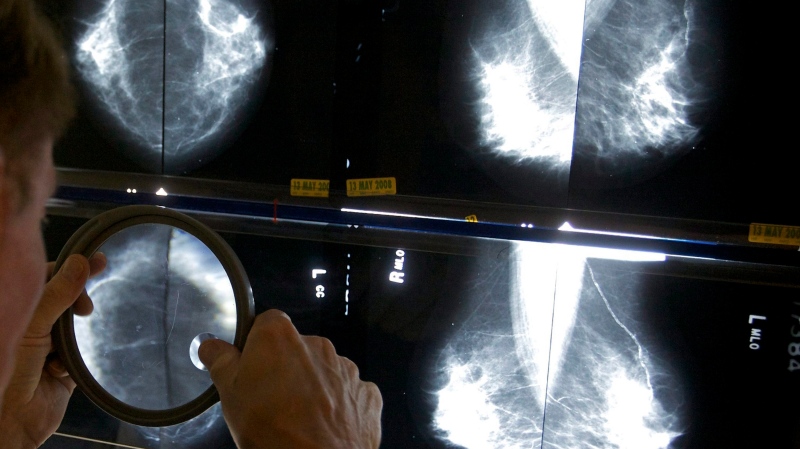

MONTREAL/TORONTO -- Medical companies and shippers in Canada are racing to transport time-sensitive radiochemical materials used to treat cancer, as a pandemic-induced drop in passenger flights has narrowed transportation options and created cargo delays.

Half of air cargo normally travels in the belly of passenger jets rather than dedicated freighters. But flight cancellations as traffic plummeted during the pandemic have left some companies scrambling to ship treatments that decay over time, pushing up overall transportation costs.

Before the pandemic, the McMaster Nuclear Reactor in Ontario could ship its iodine-125 isotope anywhere in a couple of days.

But since spring, deliveries of the isotope, used to treat about 70,000 patients a year with a procedure called brachytherapy, have been delayed as long as 10 days.

"There's fewer flights, so it's creating longer routes,” said Karin Stephenson, manager of commercial operations at the reactor. "It's been really challenging trying to get our product around."

It is a problem in Canada, where a limited domestic market and restrictions on international travel, like a 14-day quarantine for arrivals, have hit air passenger traffic harder than in some other countries like the United States. Travel volumes are down 90% at Canadian airports on an annual basis, according to the government.

U.S. cancer specialists and the American College of Radiology said they had not heard of any widespread concerns over shipping isotopes.

For the broader industry, moving medical isotopes is a challenge because they decay over time. In 10 days, iodine-125 loses about 20% of its radioactivity, said Stephenson.

Another product shipped by McMaster, holmium-166, the key raw material in a liver cancer therapy used in Europe called QuiremSpheres, has a half life of only 27 hours.

"Timing is extremely critical," said Jan Sigger, chief executive of Netherlands-based Quirem Medical, recently acquired by Japan's Terumo Corp.

Quirem supply chain manager Jerfaas Haalboom said some patients' treatments were rescheduled because of delayed shipments.

FEWER OPTIONS

Airlines are also moving to smaller planes with less cargo capacity which can lead to some goods being bumped.

"Shipments get bumped all the time because of aircraft capacity," said Mike Stopay, director of Pacer Air Freight, a Toronto-area cargo specialist.

The recent pickup in transport of COVID-19 vaccines, equivalent to about 0.3% of global air freight, is not likely to displace time-sensitive medical products in cargo planes, said Marco Bloemen, managing director of Seabury Consulting, a division of Accenture Plc.

Falling plane values, and a rise in e-commerce due to the pandemic, are also fueling a boom in converting passenger planes to freighters. Freighters have greater capacity but fly less frequently, creating a potential headache for some shippers of time-sensitive cargo.

Roy Bekic, logistic manager at the Centre for Probe Development and Commercialization in Ontario, said he depends on passenger flights to ship products to Australia via a connection in Vancouver. Delays have led him to lose a handful of shipments.

"For some of my Australian clients I have only about 90 hours before (the treatment) expires," Bekic said.

The challenges are leading to higher transport costs, either to compensate for products lost due to delays, or because companies have fewer options to ship the materials.

Stephenson said McMaster, which has to transport more material to account for longer travel times, recently raised its shipping charges, after absorbing extra costs for months.

Gabriel Freitas, an executive at Vancouver-based isoSolutions, which specializes in sourcing and distributing products in nuclear medicine, said the company has faced increases in shipping prices ranging from around 20% to 30%.

Before COVID-19, Freitas could secure lower prices by searching competing flights.

"Now you go with whatever option you get."